PRODUCT

From Tech To Innovation

3D Vision Based Robot System

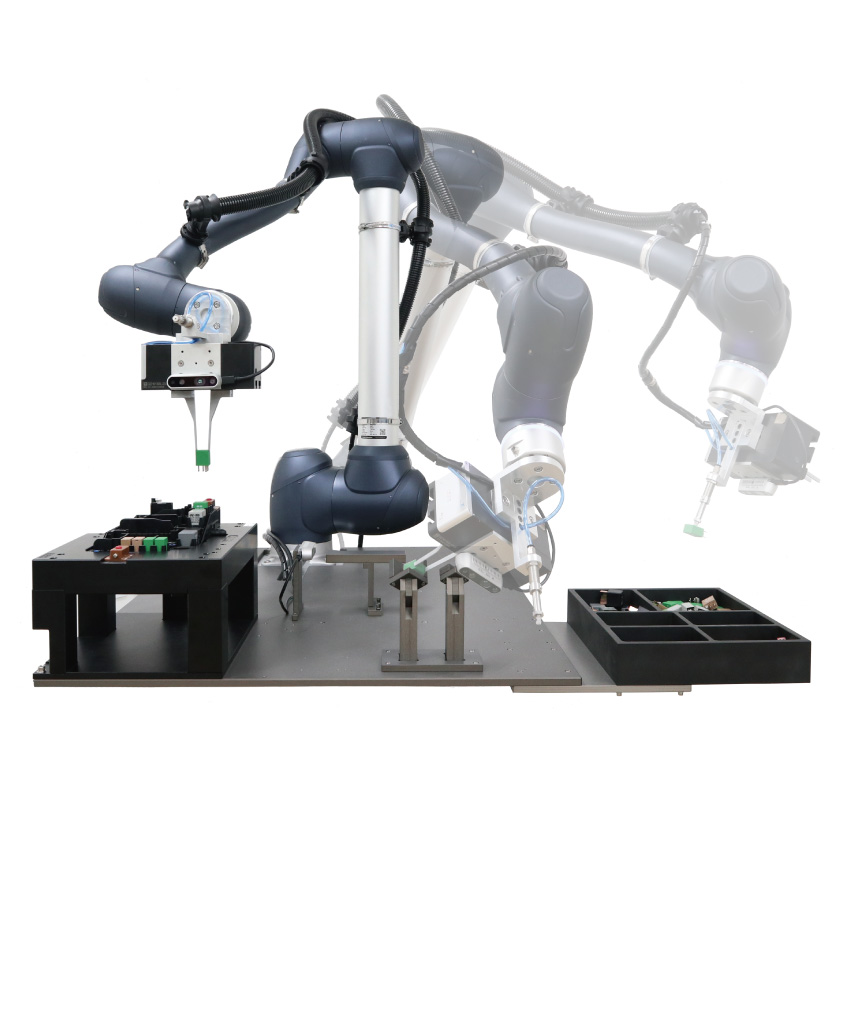

3D VISION BASED ROBOT SYSTEM

Description

- Not for sale

- Relay and Fuse automatic insertion system using a multi-joint robot

- Used in the under-hood fuse box manufacturing process: Ensures stable assembly when inserting relays and fuses

- Enables accurate part selection (pick), positioning (place), and insertion with the appropriate force

- Parts can be selected without a parts feeder using a 3D Vision System

- Prevents incorrect insertion due to accumulated worker fatigue (reducing process defect rates)

- No damage to parts that occurs in manual (traditional) processes

Technical Data - ROBOT

- DEGREE OF FREEDOM : 6

- WORKSPACE : Max. 1700 mm

- REPEATABILITY : ± 0.1 mm

- PAYLOAD : Max. 6 kg

- PRESS FORCE : Max. 16 N

Technical Data - GRIPPER

- DRIVE : BLDC Motor

- STROKE PER JAW : Max. 80 mm

- NOMINAL GRIPPING FORCE : 1800 N

Technical Data - CAMERA

- DEPTH TECHNOLOGY : Active IR Stereo

- SENSOR SHUTTER TYPE : Global Shutter

- DEPTH RESOLUTION : Up to 1280×720

- RGB RESOLUTION : UP to 1920×1080

- FRAME RATE : Up to 90fts

VIDEO